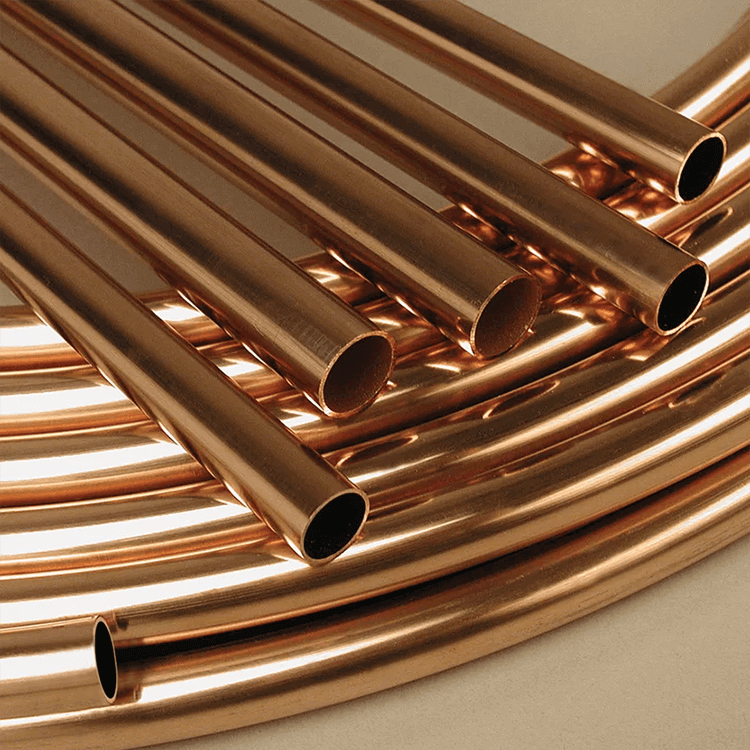

With a stock range including square and rectangular sections (also known as box sections), our copper hollow sections range is available in both metric and imperial sizes to suit your engineering needs. Typically, round hollow sections have a thicker wall compared to copper tubes. Hollow sections often save costs compared to solid bar products due to the reduction in weight while still maintaining reasonable strength.

| Grade | |

| T1,T2,C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, TP1,TP2,C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, TU1,TU2,C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000,C44300, C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70600,C70620,C71000, C71500,C71520,C71640,C72200,etc | |

| Dimension | Range |

| Thickness | 0.2mm~120mm |

| Outer Diameter | 0.2mm~120mm |

| Length | 1m,2m,3m,4m,6m,or as required |

| Process service | Bending, Decoiling, Welding, Punching, Cutting |

SINGLE SUPPLY SOURCE

We offer an effective, fast turnaround on all hollow section products, supplying your material in full or cut lengths. We handle all this for you under one roof, either at one of our China service centres or our central processing warehouse. Either way, you will receive fully traceable copper sections from us in a selection of material grades and sizes, perfect for your requirements.

USES OF COPPER HOLLOW SECTIONS

Our copper sections combine excellent corrosion resistance with high electrical conductivity. Due to the alloy's performance characteristics, our copper hollows find use in a wide variety of industrial applications, particularly in electrical engineering. Our copper products are simple to machine, drill, braze, weld, and solder.