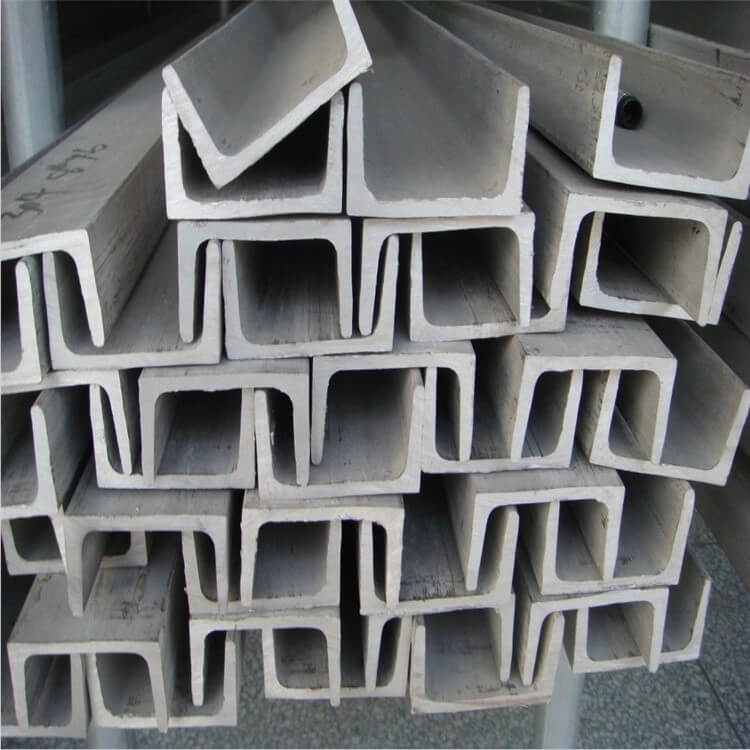

201 Stainless Steel Channels :

The destruction rate of 200 series steels under these conditions is approximately 10-100 times that of 304 stainless steels.

The residual sulfur and carbon content of these steels is often not controlled during production, and the material cannot be traced to its source, even when it is recycled.

If Cr-Mn steels are not specified, they can become a dangerous scrap mix, resulting in castings containing unexpectedly high levels of manganese.

The disadvantage of this series of materials is: below 18% chromium content and low nickel content can not reach balance and form ferrite, for this reason, 200 series of stainless steel chromium content to 13.5% ~ 15%, in some cases down to 13% ~ 14%, its corrosion resistance is not compared with 304 and other similar steels.

In addition, manganese and, in some cases, copper reduce the effect of re-passivation under acidic conditions common in the corrosion sites of deposits and crevasses.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 201 | 1.4372 | 12Cr17Mn6Ni5N | SUS201 | |

Stainless Steel 201 Chemical Comppsition :

Tensile strength :520MPa

Yield strength :275MPa

Elongation :55 to 60%

Elastic modulus :29,000,000 psi is equivalent to: 203000MPa

Hardness requirement (Brinell hardness)

183 n/was (MPa).

Density :.280 LBS /cubic inch(density 7.93g/cm3)

202 Stainless Steel Channels :

202 stainless steel is one of the 200 series stainless steel, the national standard model is 1Cr18Mn8Ni5N.

200 series stainless steel belongs to low nickel and high manganese stainless steel, nickel content, manganese content of about 8%, is a section of nickel stainless steel.

This is the most cost effective grade of steel. So the 202 Stainless Steel Sheet Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The low carbon version, 202 sheets are very good for welding applications as they have less carbide precipitation and less localized corrosion.

Stainless Steel 202 Chemical Comppsition :

304 Stainless Steel Channels :

The thinner sheets have higher strength values. The specification of the sheets is the A240 for pressure vessel and high temperature applications. The ASTM A240 SS 304 Sheet can withstand high temperatures up to 870 degrees Celsius. The sheets are used for this reason in evaporators, heat exchangers and in other high temperature applications. The Stainless Steel 304 Plate is also used in drums, barrels, dairy equipment, food processing and in hospital equipment.

This is the most cost effective grade of steel. So the 304 Stainless Steel Channels Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The sheets and UNS S30400 Stainless Steel Strip Specification varies and the applications differ for the different versions of the material. The low carbon version, 304L are very good for welding applications as they have less carbide precipitation and less localized corrosion. Please contact us for more information and prices.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 304 | S30400 | 304S15 | 58E | 1.4301 | X5CrNi18-10 | 0Cr18Ni9 | SUS304 |

Stainless Steel 304 Chemical Comppsition:

304L Stainless Steel Channels :

304L stainless steel is a kind of universal stainless steel material.

304L stainless steel grade:

The old standard JB/T 4237-1992 corresponds to 00Cr19Ni10

New standard GB/T 20878-2007 Stainless steel and heat resistant steel grades and chemical composition

And GB 24511 2009 stainless steel plates and strips for pressure bearing equipment

The above corresponds to 022Cr19Ni10, which contains about 0.03% carbon

Uniform digital code S30403 is different from S30408 of 304

This is the most cost effective grade of steel. So the 304L Stainless Steel Channels Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The low carbon version, 304L sheets are very good for welding applications as they have less carbide precipitation and less localized corrosion.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 304L | 1.4307 | 00Cr19Ni10 | SUS304L | |

Stainless Steel 304L Chemical Comppsition :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 304L | Min. Max. | ≤0.03 | ≤2.0 | ≤1.00 | ≤0.045 | ≤0.03 | 18.0~20.0 | / | 9.0~12.0 | |

309S Stainless Steel Sheet :

309S corresponding to the Chinese brand is 0Cr23Ni13, the American standard S30908 (AISI, ASTM) characteristics and use: corrosion resistance, heat resistance are better than 0Cr19Ni9.

The 309S is a variant of the lower carbon 309 stainless steel for use where soldering is required.

The lower carbon content minimizes the precipitation of carbides in the heat affected zone near the weld, which may lead to intergranular corrosion (welding erosion) of stainless steel in some environments.

It can withstand repeated heating below 980 ℃, and has high high temperature strength, oxidation resistance and carburizing resistance.

Application: Furnace material.

Widely used in boilers, energy (nuclear power, thermal power, fuel cell), industrial furnaces, incinerators, heating furnaces, chemical, petrochemical and other important fields.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

310S Stainless Steel Channels :

310S stainless steel is austenitic chromium-nickel stainless steel, has good oxidation resistance, corrosion resistance, high temperature resistance, because of the higher percentage of chromium and nickel, making it has much better creep strength, can continue to work at high temperature, has good high temperature resistance.

Because of the high content of nickel (Ni), chromium (Cr), has good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature resistance, high temperature resistant steel pipe is dedicated to the manufacture of electric furnace tube and other occasions, austenitic stainless steel increases the content of carbon, due to its solid solution strengthening effect so that the strength is improved,

The austenitic stainless steel has high strength and creep strength at high temperature due to its face-centered cubic structure, which is based on chromium and nickel.

Melting point 1470℃, 800℃ began to soften, allowable stress continued to reduce.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 310S | 1.4951 | 06Cr25Ni20 | SUS310S | |

Stainless Steel 310S Chemical Comppsition :

316 Stainless Steel Channels :

316 stainless steel because of the addition of Mo element, so that its corrosion resistance, and high temperature strength has been greatly improved, high temperature resistance can reach 1200-1300 degrees, can be used under harsh conditions.

Application: Seawater equipment, chemical, dye, paper making, oxalic acid, fertilizer and other production equipment;

Photographs, food industry, coastal facilities, ropes, CD rods, bolts, nuts.

Characteristics: Because of the addition of Mo, it has good corrosion resistance, atmospheric corrosion resistance and high temperature strength, which can be used under harsh conditions;

Excellent work hardening (non-magnetic);

Excellent high temperature strength;

The solid solution state is not magnetic;

Cold rolled product appearance gloss is good, beautiful;

Relative to 304 stainless steel, the price is higher.

316 stainless steel because of the addition of Mo element, so that its corrosion resistance, and high temperature strength has been greatly improved, high temperature resistance can reach 1200-1300 degrees, can be used under harsh conditions.

Application: Seawater equipment, chemical, dye, paper making, oxalic acid, fertilizer and other production equipment;

Photographs, food industry, coastal facilities, ropes, CD rods, bolts, nuts.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 316 | 1.4401 | 0Cr17Ni12Mo2 | SUS316 | |

Stainless Steel 316 Chemical Comppsition :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | Min. Max. | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.035 | ≤0.03 | 16.0-18.5 | 2.0-3.0 | 10.0-14.0 | |

316L Stainless Steel Channels :

316L has a wide range of applications in the chemical industry because of its excellent corrosion resistance. 316L is also a derivative of 18-8 austenitic stainless steel, with 2 ~ 3% Mo element added.

On the basis of 316L, many kinds of steel are also derived. For example, 316Ti is derived after adding a small amount of Ti, 316N is derived after adding a small amount of N, and 317L is derived by increasing the content of Ni and Mo.

Most of the existing 316L in the market are produced according to American standards.

For cost consideration, steel mills generally put the Ni content of products as far as possible by the lower limit.

The American standard stipulates that the Ni content of 316L is 10 ~ 14%, while the Japanese standard stipulates that the Ni content of 316L is 12 ~ 15%.

According to the minimum standard, there is a 2% difference between the American standard and Japanese standard in the Ni content, which is still quite huge in the price. Therefore, customers still need to see clearly when buying 316L products, whether the products refer to ASTM or JIS standards.

The Mo content of 316L makes the steel have excellent pitting resistance and can be safely used in environments containing Cl- and other halogen ions.

Because 316L is mainly used for its chemical properties, steel mills have slightly lower requirements for surface inspection of 316L (relative to 304), and customers with higher surface requirements should strengthen surface inspection.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 316L | 1.4404 | 022Cr17Ni12Mo2 | SUS316L | |

Stainless Steel 316L Chemical Comppsition :

Tensile strength σb (MPa) : ≥480

Conditional yield strength σ0.2 (MPa) : ≥177

Elongation Δ5 (%) : ≥40

Section shrinkage ψ(%) : ≥60

Hardness: 187 hb or less;

90 HRB or less;

200 hv or less

Density: 7.98g/cm3;

Specific heat capacity ratio (20℃) : 0.502J/(g*K)

321 Stainless Steel Channels :

Austenitic stainless steel equivalent to domestic grade 0Cr18Ni10Ti 321 stainless steel is Ni-Cr-Mo type austenitic stainless steel, its performance is very similar to 304, but due to the addition of titanium, so that it has a better resistance to grain boundary corrosion and high temperature strength.

Due to the addition of titanium, the formation of chromium carbide is effectively controlled.

321 austenitic stainless steel has good corrosion resistance in the atmosphere, and is widely used in petrochemical, electric power, bridge and automobile industries.

But the stainless steel "rust" is not absolute, because of the special service environment, stainless steel will also occur corrosion.

Medium concentration, pH value, temperature and other factors will have a greater impact on the corrosion resistance of stainless steel.

For example, in the range of 450~850℃ sensitization temperature long-term use, stainless steel will occur intergranular corrosion.

The mechanism is that C combines with Cr at grain boundary to form Cr23C6 and precipitates out, which reduces Cr content at grain boundary, which is the so-called "poor chromium".

The Cr element is one of the main elements to inhibit the intergranular corrosion. When the Cr content at the grain boundary is less than 12%, the probability of intergranular corrosion will increase.

| Grade | Euronorm | China GB | Japanese JIS | Germany | |

| No. | |||||

| 321 | 1.4541 | 0Cr18Ni10Ti | SUS321 | X10CrNiTi189 | |

Stainless Steel 321 Chemical Comppsition :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 321 | Min. Max. | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 17.00-19.00 | / | 9.00-12.00 | 0.1 |

409L Stainless Steel Channels :

409L high temperature resistance, can achieve high efficiency of the engine and exhaust system, and reduce the thickness of the exhaust system, can reduce exhaust emissions.

409L low cost, good flexibility, high rate of finished material, easy to replace, belongs to the environmental protection of new products.

| Grade | Euronorm | Japanese JIS | ISO | |

| No. | ||||

| 409L | 1.4512 | SUH409L | X2CrTi12 | |

Stainless Steel 419L Chemical Comppsition :

(1) When 409L steel crystallizes, the solid-liquid two-phase zone is very small, less than 30℃;

(2) There is almost no γ phase at high temperature.

The carbon content of 409L steel is very low, even if δ phase is present, the amount is very small.

Therefore, there is no significant impact on performance.

409L steel from high temperature to low temperature almost no α→γ phase transformation, so the grain is easy to grow up, there are thick ferrite structure, low strength, in continuous casting, after the slab is cut up, prone to bend phenomenon, affect the normal production.

The main problem during crystallization of 409L steel is the degradation of properties caused by coarse grain size≥192HB

410S Stainless Steel Channels :

1) High strength;

2) Excellent machinability

3) Hardened after heat treatment;

4) Magnetic;

5) not suitable for harsh corrosive environment.

Scope of application

General blade, mechanical parts, class 1 tableware (spoon, fork, knife, etc.).

This is the most cost effective grade of steel. So the 410S Stainless Steel Sheet Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The low carbon version, 410S sheets are very good for welding applications as they have less carbide precipitation and less localized corrosion.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 410S | 1.4000 | 1Cr13 | SUS410S | |

Stainless Steel 410S Chemical Comppsition :

430 Stainless Steel Channels :

430 stainless steel has the ability of oxidation resistance to corrosion, but has the tendency of intergranular corrosion.

430 stainless steel wire is widely used in the axis.

As safe and non-toxic, it is widely used in food tableware.

This is the most cost effective grade of steel. So the 430 Stainless Steel Sheet Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The low carbon version, 430 sheets are very good for welding applications as they have less carbide precipitation and less localized corrosion.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 430 | 1.4016 | 10Cr17 | SUS430 | |

Stainless Steel 430 Chemical Comppsition :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 430 | Min. Max. | ≤0.12% | ≤1.00% | ≤0.75% | ≤0.040% | ≤0.030% | 16.00~18.00% | / | ≤0.60% | |

444 Stainless Steel Channels :

444 steel belongs to high alloy ferritic stainless steel, compared with the commonly used steel SUS430:1.

The chromium content is about 1.0% high, and the alloying element molybdenum (Mo) is added, so the steel has good resistance to pitting corrosion, crevices corrosion, stress corrosion ability, its corrosion resistance in some areas even better than SUS304 and SUS316.

2. Add titanium (Ti), niobium (Nb), zirconium (Zr) and other stabilized elements, so the steel has good intergranular corrosion resistance and high temperature oxidation resistance.

The old brand is 00CR18MO2, the new brand is 019CR19MO2NB1Ï

, the uniform digital code is S11972 (GB/T 20878-2007)

This is the most cost effective grade of steel. So the 444 Stainless Steel Sheet Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The low carbon version, 444 sheets are very good for welding applications as they have less carbide precipitation and less localized corrosion.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 444 | 1.4521N | 00Cr18Mo2 | SUS444 | |

Stainless Steel 202 Chemical Comppsition :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 444 | Min. Max. | ≤0.025 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 17.5~19.5 | 1.75~2.5 | ≤1.00 | ≤0.035 |

904L Stainless Steel Channels :

Super austenitic stainless steel 904L (00Cr20Ni25Mo4.5Cu;

UNS: N08904;

EN: 1.4539) is a low carbon, high-alloy austenitic stainless steel with excellent corrosion resistance in dilute sulfuric acid. It is designed for harsh corrosion conditions.

Has the high chromium content and plenty of nickel content, the addition of copper makes it have strong ability to resist acid, especially for chloride clearance corrosion and stress corrosion cracking are highly resistant, not easy to appear, erosion and fracture pitting resistance slightly better than other steel grade, good machinability and weldability, can be used for pressure vessels.

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 904L | 1.4539 | 00Cr20Ni25Mo4.5Cu | SUS904L | |

Stainless Steel 904L Chemical Comppsition :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | |

| 904L | Min. Max. | ≤0.03 | ≤2.00 | ≤1.00 | ≤0.035 | ≤0.03 | 18.0-20.0 | 3.0-4.0 | 23.0-25.0 | 4.0-5.0 |

2205 Stainless Steel Channels :

The yield strength of 2205 duplex stainless steel is more than double that of ordinary austenitic stainless steel. This characteristic allows designers to reduce weight when designing products, giving this alloy a price advantage over 316,317L.

This alloy is particularly suitable for the temperature range of -50°F/+600°F.

For applications beyond this temperature range, this alloy may also be considered, but there are some limitations, especially when applied to welded structures.

Due to the chromium (22%), molybdenum (3%) and nitrogen (0.18%) content,2205 has better corrosion resistance than 316L and 317L in most environments.

Local corrosion resistance

The content of chromium, molybdenum and nitrogen in the 2205 duplex stainless steel makes it highly resistant to pitting and gap corrosion in oxidizing and acidic solutions.

Stress corrosion resistance

The two-phase microstructure of stainless steel is helpful to improve the stress corrosion cracking resistance of stainless steel.

Chloride stress corrosion occurs in austenitic stainless steels under certain temperature, tension, oxygen and chloride conditions.

As these conditions are not easily controlled, the use of 304L, 316L and 317L is limited in this regard.

Corrosion fatigue

The high strength and corrosion resistance of 2205 duplex steel make it have high corrosion fatigue strength.